Engineering Design Coursework

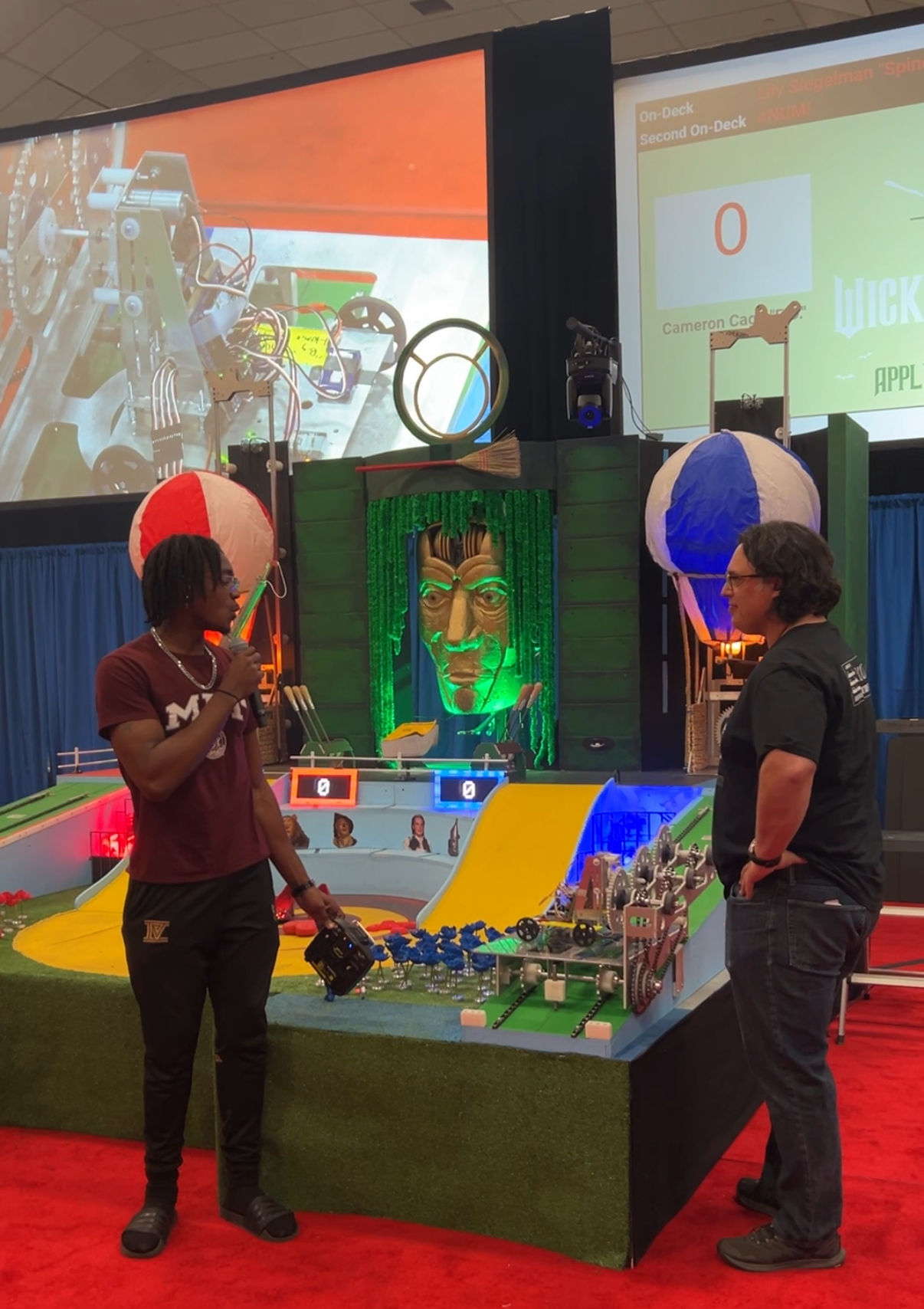

"Wicked FBD: Defying Gravity" Robot Competition

Project Overview

Spring 2025, MIT course 2.007 – Design & Manufacturing I. Designed, fabricated, and programmed a dual-mode competition robot (affectionately dubbed "Big Homie") from concept to deployment within 13 weeks. The robot competed in a Wizard of Oz-themed challenge requiring navigation across vertical obstacles, autonomous operation, and hybrid manual/autonomous control. Awarded the Glinda Prize for "the most elegant, regal, and stunning robot," recognizing technical execution, autonomous systems integration, and design elegance

Advisor: Prof. Joshua Wiesman

Design Challenge

The competition theme: "Defying Gravity" required robots to score points across multiple obstacles including climbing a 30° inclined train track, raising a weighted hot air balloon, and manipulating game elements autonomously within a 30-second window.

Key constraints included:

Size: Robot must fit within 12" × 12" × 16" starting volume

Weight: 12 lb maximum; lighter robots earned scoring multipliers and tiebreaker advantages

Time: Full design-to-fabrication cycle compressed into 10 functional weeks (13-week semester minus initial concept phase)

Materials: Limited to lab-supplied components; max 8 motors, 6 in³ of 3D-printed parts, and 1 hour of waterjet cutting time

Energy: 50 kJ stored energy limit across batteries, compressed air, and elastic systems

Technical Approach

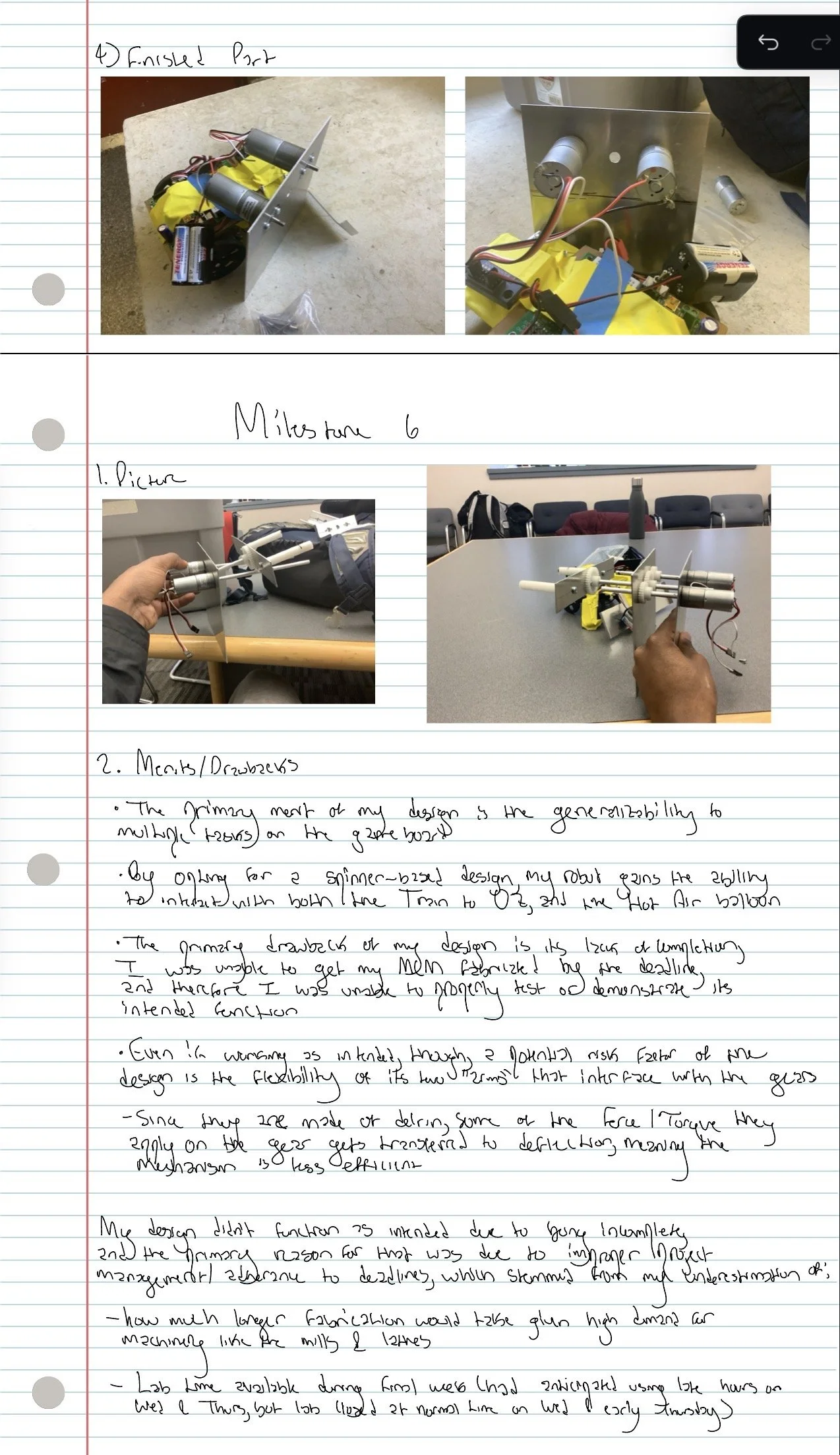

My strategy centered on a spinner-based flywheel mechanism capable of interfacing with rotary obstacles (train gear and balloon winch) through adjustable-height engagement. Core design decisions:

Drive Train & Actuation

Custom gearbox with tab-slot adjustable mounting allowing on-the-fly height reconfiguration without disassembly—critical for adapting to field variations between competition rounds

Dual-motor flywheel system transferring torque through spur gears (calculated requirement: 0.762 Nm to drive train mechanism)

Sheet metal chassis with cantilevered L-bracket constraints, minimizing friction while maintaining 1-DOF shaft alignment

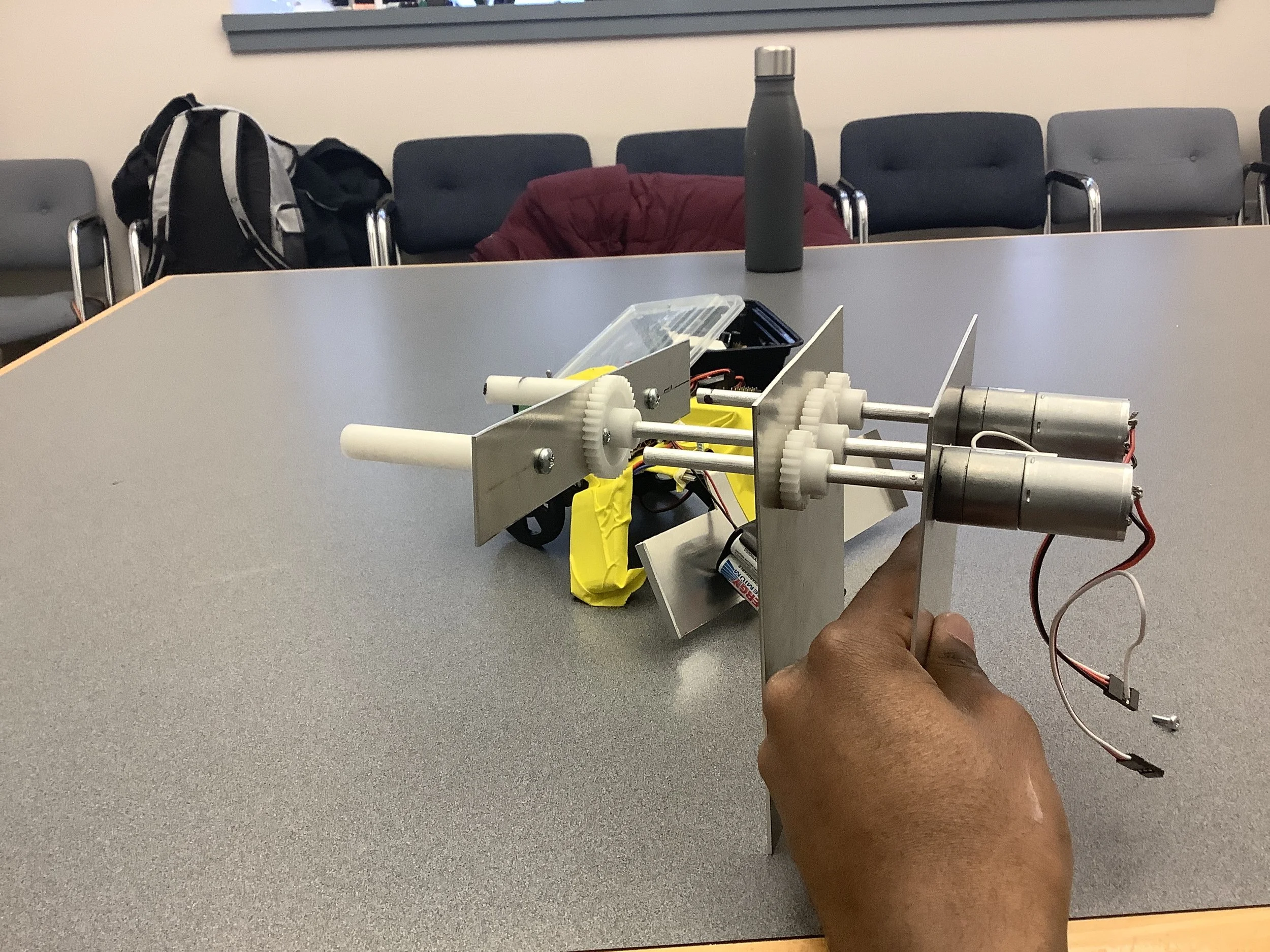

Initial Prototype of Gearbox + Drive Train prior to mounting

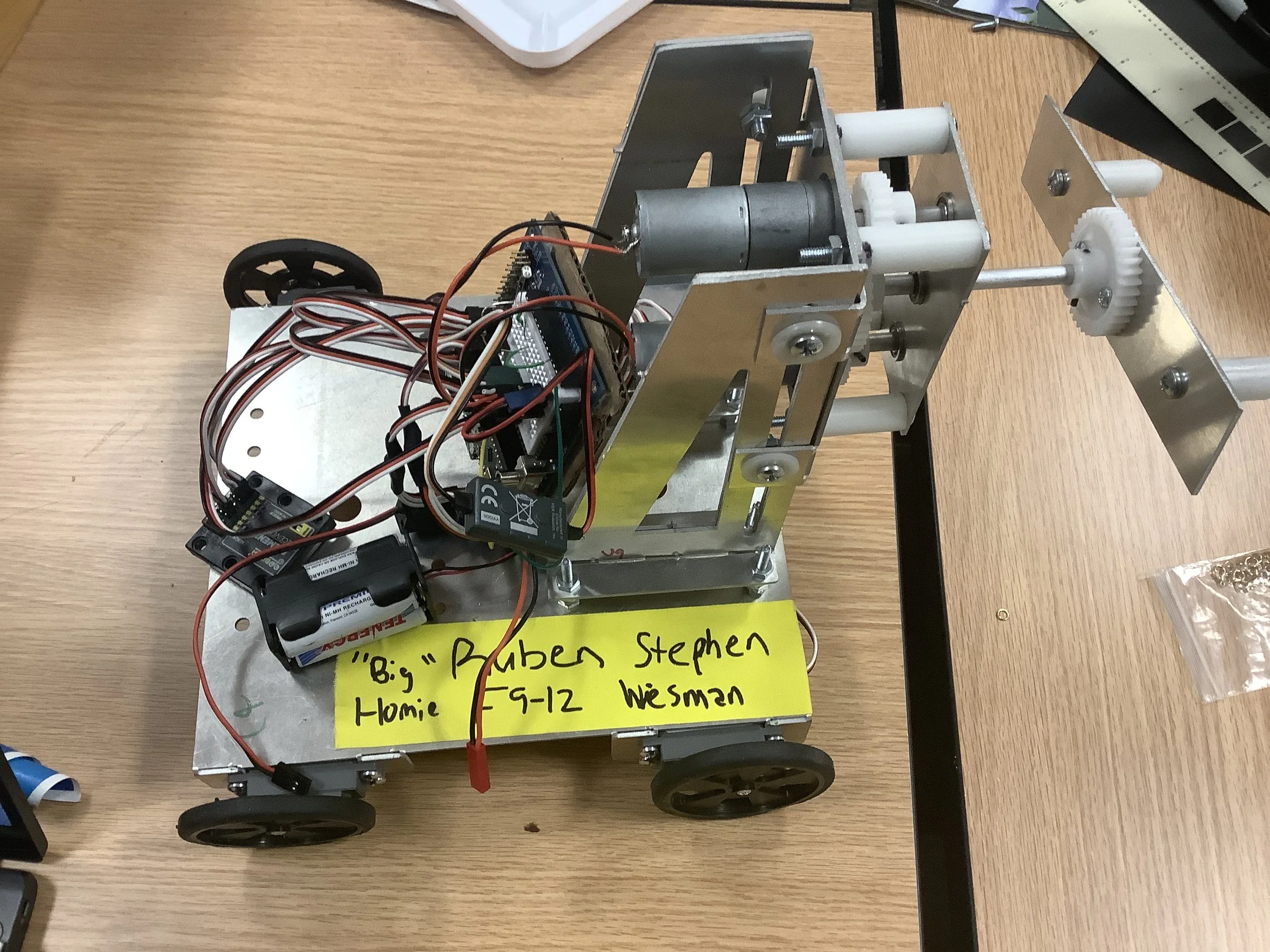

Gearbox and Drive train mounted to robot chassis via tab-slot design

Autonomous Control Logic

Photoelectric sensor trigger system for autonomous period initialization (rules prohibited physical contact to start)

Programmed autonomous-to-manual mode switching after first obstacle clearance, maximizing doubled autonomous scoring while preserving manual control for complex maneuvers

Achieved 50% reliability (5/10 consecutive test runs) completing both train and balloon tasks within the 2-minute match window

Video demonstration of photoelectric sensor trigger system for autonomous period

Video demonstration of autonomous-to-manual operation for completion of both Train and Balloon challenges

Iterative Prototyping & Fabrication

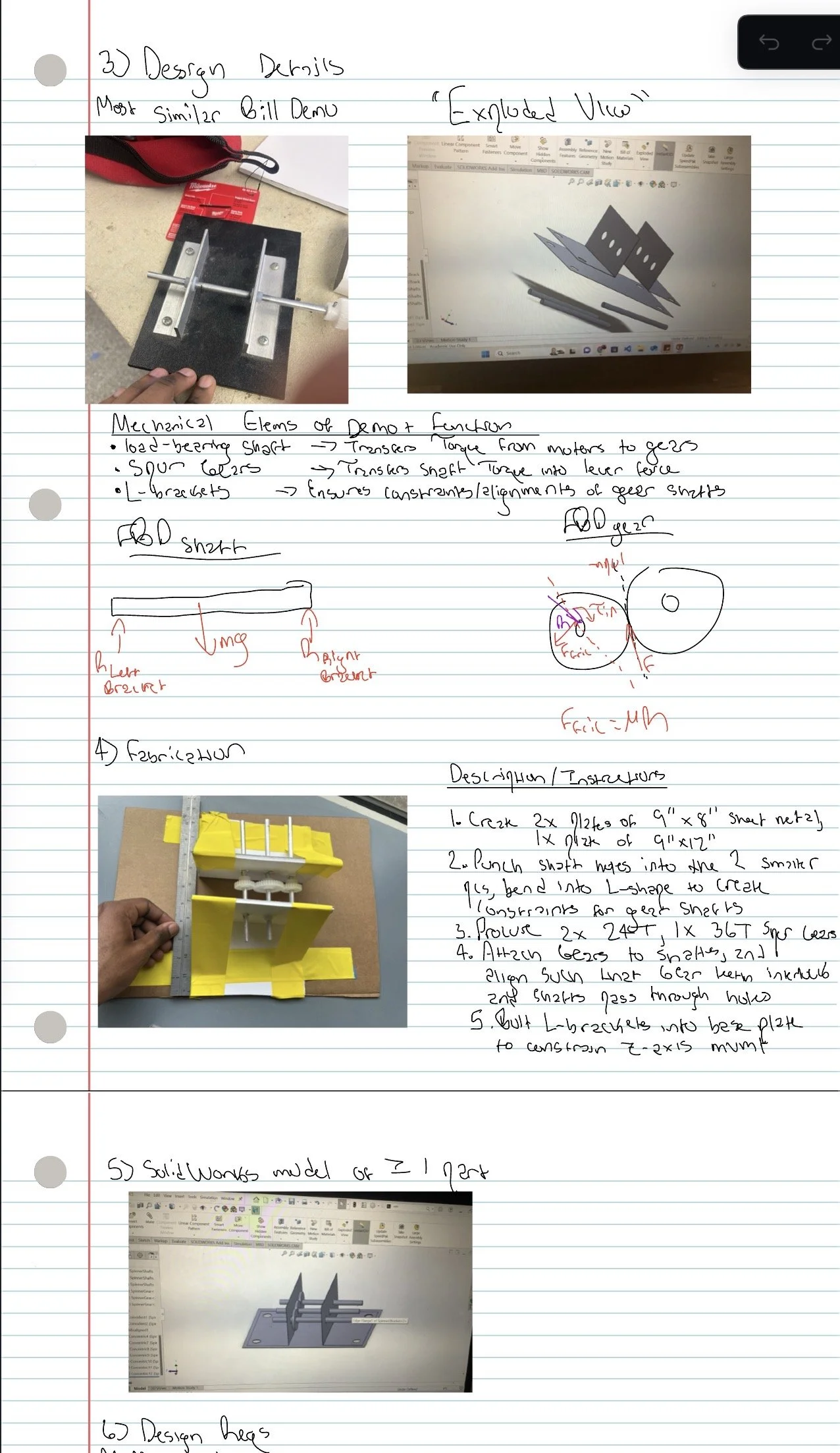

CAD modeling in SolidWorks with assembly simulations before fabrication

Hand calculations for center-of-mass positioning to prevent tipping on incline (coefficient of friction testing: μ = 0.473)

Machined components using mill, lathe, waterjet, and manual fabrication techniques; debugged motor stall issues through gear ratio redesign mid-competition

Outcomes & Recognition

Successfully demonstrated hybrid autonomous/manual operation under competition constraints

Implemented modular reconfiguration strategy allowing adaptation between left/right field sides within 5-minute setup windows

Glinda Prize Winner: Awarded for "most elegant, regal, and stunning robot" based on technical sophistication, autonomous functionality, and creative engineering execution